짜임새 간장 또는 야채 단백질 음식 기계장치

거래 세부 정보

| 공급 능력: | 30 세트 / 월 |

|---|---|

| 포장: | 나무 상자 |

| 배송 시간: | 30 작업 일 |

Product Details

Quick Details

| Place of Origin: | China (Mainland) | Brand Name: | saixin |

|---|---|---|---|

| Model Number: | sx | Type: | Texture Soya/Vegetable Protein Food Machinery |

| dimension: | 15*1.2*1.8m | power: | 65kw |

Specifications

stainless steel

easy to operate

fully automatic

CE certificate

Soyabean protein food processing line.

easy to operate

fully automatic

CE certificate

Soyabean protein food processing line.

Brief introduction:

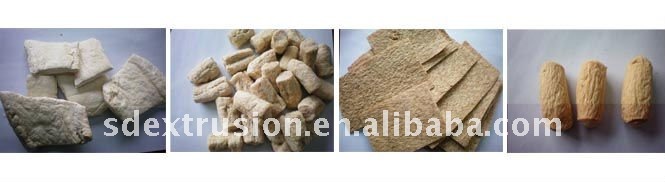

500kg/h Textured soyabean protein processing line uses soybean powder, peanut powder and isolates protein as main raw material to produce high protein, low fat food additives. It has advantages of high nutritional value, without cholesterol or animal fat, at the same time it has the status of meat and taste and the features such as oil-absorbing, odor absorption, water absorption. Currently it is widely used in the meat industry, frozen food industry etc. It has the characteristic of simple device, high automatic level. The performance fully reach the advanced country's.

1. Soya protein food processing line uses soybean powder and peanut powder to break spherical protein molecule to form chain protein molecule thus creating slice-like and high-cutting.

2. The product is nutritious without cholesterol or animal fat, but it looks like and tastes like meat with the quality of absorbing soil, water, and flavor.

2.The screws are made by alloy steel and special craft, the screw life is longer, uses building block system structure, may combine willfully.The forced lubrication system, by guaranteed equipment transmission longer lifespan

Visible auto-temperature controlling system, make the temperature-controlling to be more direct-viewing, parameter to be more precise.

This line contains the following machine: Mixer --Screw Conveyor --Conditioner--Twin Screw Extruder--Air conveyor--Oven.

Technical parameter:

-------------------------------------------------------------------------------------

500kg/h Textured soyabean protein processing line uses soybean powder, peanut powder and isolates protein as main raw material to produce high protein, low fat food additives. It has advantages of high nutritional value, without cholesterol or animal fat, at the same time it has the status of meat and taste and the features such as oil-absorbing, odor absorption, water absorption. Currently it is widely used in the meat industry, frozen food industry etc. It has the characteristic of simple device, high automatic level. The performance fully reach the advanced country's.

1. Soya protein food processing line uses soybean powder and peanut powder to break spherical protein molecule to form chain protein molecule thus creating slice-like and high-cutting.

2. The product is nutritious without cholesterol or animal fat, but it looks like and tastes like meat with the quality of absorbing soil, water, and flavor.

3. The complete line includes Mixer, extruder, dryer and flavoring line

Main characteristic:

1.Textured Vegetable Soya Protein Food Processing Line use the defatted soya/peanut flour as the raw material.Main feature: low production cost and high profit.Through this Texture Soya protein machine, the materials can be reorganized and shaped into different shapes such as pipe, stick, ball and more.As Texture Soya protein machine makes more concentrated and healthy protein, it has become the most popular line in the world2.The screws are made by alloy steel and special craft, the screw life is longer, uses building block system structure, may combine willfully.The forced lubrication system, by guaranteed equipment transmission longer lifespan

Visible auto-temperature controlling system, make the temperature-controlling to be more direct-viewing, parameter to be more precise.

This line contains the following machine: Mixer --Screw Conveyor --Conditioner--Twin Screw Extruder--Air conveyor--Oven.

Technical parameter:

4. Parameters

| ||||||||||

|

-------------------------------------------------------------------------------------

짜임새 간장 또는 야채 단백질 음식 기계장치

거래 세부 정보

| 공급 능력: | 3 세트 / 월 |

|---|---|

| 포장: | 나무로 되는 케이스 |

| 배송 시간: | 30 일 |

Product Details

Quick Details

| Place of Origin: | China (Mainland) | Brand Name: | SAIXIN |

|---|---|---|---|

| Model Number: | SX65 | Power: | 65kw |

| Dimension: | 14000*1200*2300mm | capacity: | 240kg/h |

| material: | stainless steel | Application: | soya protein food machines |

Specifications

1.soy protein food machine

2.with the defeated soyabean powder as the main materials

3.Texture soya meat protein machine

2.with the defeated soyabean powder as the main materials

3.Texture soya meat protein machine

1.soy protein food machine

2.with the defeated soyabean powder as the main materials

3.Texture soya meat protein machine

4. Three layer Oven

2.with the defeated soyabean powder as the main materials

3.Texture soya meat protein machine

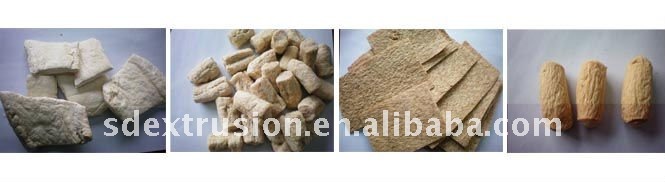

Protein food processing line is the new extruder we specially designed for plant protein extrusion.It processes low temperature soyabean powder and peanut meal to meat-like food that can be added to ham,sausage,canfood,fastfood and deepfreeze food for more taste.

1. Soya protein food processing line uses soybean powder and peanut powder to break spherical protein molecule to form chain protein molecule .

2. The product is nutritious without cholesterol or animal fat, but it looks like and tastes like meat with the quality of absorbing soil, water, and flavor.

3. This kind of food has high nutrition and can be widely applied in many industries: ham, cam, fast-food, instant-cool food etc.

4.The complete line includes Mixer, extruder, dryer and flavoring line

Machines involved in Texture Soya/Vegetable Protein Food Processing line:

1. Flour Mixer

To mix defeated soyabean powder with water

2. Twin screw Extruder

To cook the soyabean powderl and extrude in different shapes.

3. Air conveyor

Take the extruded snack into oven or drying

1. Flour Mixer

To mix defeated soyabean powder with water

2. Twin screw Extruder

To cook the soyabean powderl and extrude in different shapes.

3. Air conveyor

Take the extruded snack into oven or drying

4. Three layer Oven

Drying snacks

Parameters

Model

|

SX 65-I twin screw extruder

|

Installed capacity

|

85kw

|

Real power

|

65kw

|

Capacity

|

150-200kg/h

|

Dimension

|

11000×1200×2300mm

|

=================================================================

큰 수용량 콩 단백질 생산 라인

거래 세부 정보

| 공급 능력: | 10 세트 / 월 |

|---|---|

| 포장: | 나무로 되는 수출 케이스 |

| 배송 시간: | 예금의 영수증 후에 45 일 |

Product Details

Quick Details

| Place of Origin: | China (Mainland) | Brand Name: | QIDONG |

|---|---|---|---|

| Model Number: | SPH-90 | Type: | Soybean Machinery |

| Capacity: | 800-1200kg/h |

Specifications

Textured Soya/ Vegetable Protein Food Processing Line; Automatic control, Large output, Advanced Technology, Long Lifespan.

Textured Soy Protein comes in small dry chunks resembling, well, dried vegetables more than anything, or in a finely-ground form. It's flavorless, but when you rehydrate it and add your own flavors, it makes a great protein-filled addition to many dishes calling for ground meat. Because of its varying texture, it's versatile, and can take on the texture of many meats. For instance, it's excellent in chili, tacos, veggie burgers and soups.

With muscle structure, it has better absorbency, and can defend without cholesterol. It can be boiled in high temperature with different tastes, or added into meal product as stuffing. When it's used to replace meat in stews and soups, your family will hardly be able to tell the difference and since you can marinate it in many of the same sauces as meat, it can take on many of meat's flavors. We have been in researching and developing TVP/TSP food for almost ten years. We have provided many processing lines for domestic and overseas clients. We also can custom-tailor special type extruder according to different texturized demands from clients.

SPH-90 Technical parameters:

Install power: 105kw

Power consumption: 70-80kw

Main power: 55kw

Capacity: 800-1200kg/h

Dimension: 39000*2500*5000

Production process:

Milling Plant—Double-screw Extruder—SPH-90 Double-shaft pre-conditioner—Air conveyor—Spreader—Air compressor—Steam Dryer—Sprayer—Rotary mixer—Belt conveyor—Cooling machine—Packaging hopper

With muscle structure, it has better absorbency, and can defend without cholesterol. It can be boiled in high temperature with different tastes, or added into meal product as stuffing. When it's used to replace meat in stews and soups, your family will hardly be able to tell the difference and since you can marinate it in many of the same sauces as meat, it can take on many of meat's flavors. We have been in researching and developing TVP/TSP food for almost ten years. We have provided many processing lines for domestic and overseas clients. We also can custom-tailor special type extruder according to different texturized demands from clients.

SPH-90 Technical parameters:

Install power: 105kw

Power consumption: 70-80kw

Main power: 55kw

Capacity: 800-1200kg/h

Dimension: 39000*2500*5000

Production process:

Milling Plant—Double-screw Extruder—SPH-90 Double-shaft pre-conditioner—Air conveyor—Spreader—Air compressor—Steam Dryer—Sprayer—Rotary mixer—Belt conveyor—Cooling machine—Packaging hopper

댓글 없음:

댓글 쓰기